Why take this lesson?

This lesson brings awareness to the potential dangers that could be lurking on your covert IFF patch.

In this lesson you will learn:

- Avoid a patch that reflects white light

- Low glow in a patch is a no no

- Two-layer patches breakdown quickly

Your Covert Friend or Foe Patch

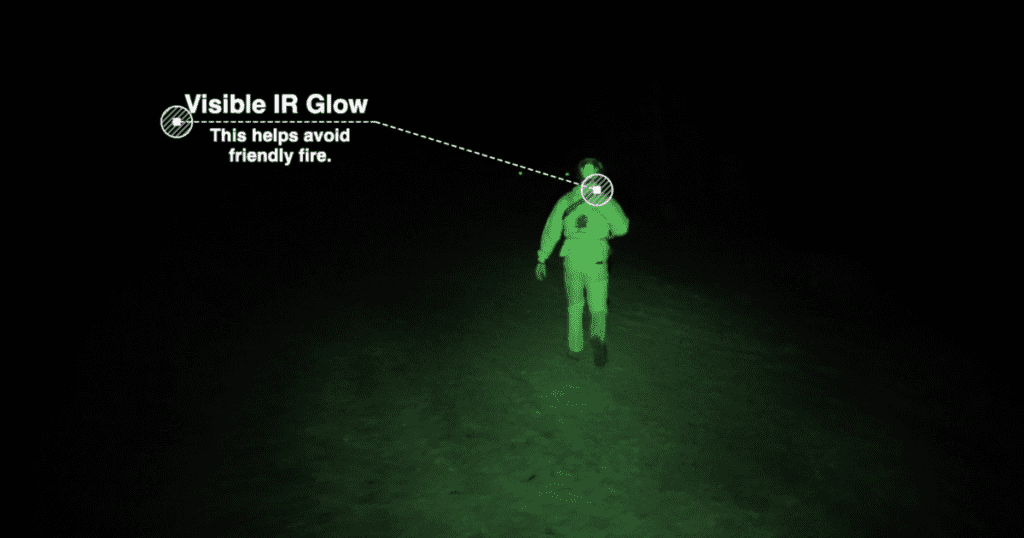

A covert IFF patch is built with a reflective film that bounces light back to the light source, signaling its location.

The light source is an IR illuminator. When the illuminator light detects the IR patch, the patch glows, and indicates “friendly.”

No shots are fired and everyone is safe.

However, potential dangers could be lurking on a faulty IR patch, and we will review these risks in this lesson.

1. Does Your Covert Patch Reflect White Light?

A covert IFF patch should not reflect white light.

The danger arises when your covert IFF patch reflects white light. It should only reflect light from an IR illuminator to maintain its covert status.

Be cautious of cheap faux IR patches available on the internet. These patches may claim to offer protection but can make you vulnerable by reflecting white light.

It is recommended to test your IR patches against any white light reflection. Take it into a dark environment and shine a flashlight on it. If the patch reflects the light, the patch will not keep you hidden from an enemy.

2. At what Distance is the Patch’s Glow Effective?

Another potential danger is a low glow distance from your patch.

If the glow on the patch is dull and can’t be seen at a distance of 700m (with PVS-14), you are at risk.

Always double-check the glow distance of your IR patch with a Night Vision device before deployment to ensure its effectiveness and safety.

3. Does Water or Debris Compromise Patch?

Patch failure due to multiple layers and poor adhesion allows for water and debris to compromise the patch. After a few months of wear and tear the layers begin to deteriorate and fall apart at the seams.

A patch failure because of faulty seams puts you at risk for friendly fire.

Manufacturer’s cost-cutting measures, cheap raw materials, lack of testing, and low standards all lead to this type of patch failure.

To be sure your patch is safe check the quality standards of your brand.

High-Quality IFF Patch

IR.Tools Field IR Reflective patch checks all the boxes when it comes to a premium covert patch.

This patch is built with a proprietary process called SandStorm Technology™ and boasts of these features:

- An exclusive black coating that resists white light reflection to keep you safe.

- Over 100k micro-prisms to provide maximum glow over 700m.

- One seamless layer with no air gaps prevents destruction from water or debris.

Conclusion

Thanks for taking the time to learn how the quality of your IR patch matters. Use this information to guide you toward evaluating a safe and effective covert IFF patch.

There is more to explore with your IFF protection so let’s get it done!

If you have any questions or have some feedback be sure to contact me.

Tom Boyer: 292-443-8885 or tboyer@ir.tools.

Continue your learning by moving on to the next lesson: The Passive vs Active IFF Debate