Does your work put you in danger of friendly fire?

Are you confident your IFF protection is reliable?

There are many options on the internet for IR patches. The cost varies from very cheap to a bit pricey.

So what’s the difference?

The difference could be a matter of life and death to you. So we advise you to be careful when choosing your patch. Because many are not built to withstand the rigors of your deployment.

Before you find yourself in a dangerous operation, do some homework and put your IR patch to the test.

Check your patch for these 5 qualities and stay safe.

1. Your IR Patch Will Not Fall Apart

It should go without saying, but you want an IR patch that will not fall apart.

The majority of IR patches circulating are made with a 2 layer process. The seams are not properly secure which leaves the patch vulnerable to degradation. As a result, the patch peels apart at the seams.

IR.Tools solved this problem by building a patch with a unique one-layer process. The patch does not fall apart at the seams because no seams exist!

We call this exclusive process – SandStorm Technology™.

A SandStorm patch will stay intact for a very long time and you won’t second guess the durability.

2. Your IR Patch Resist Water

Water can ruin just about anything.

In the case of your IR patch, you don’t want to worry if your patch is exposed to water.

An IR.Tools™, SandStorm Technology™ patch stays intact and glows before and after it takes a swim.

Though we don’t recommend throwing it in the washing machine.

3. Your IR Reflection is Bright

Often we come across IR patches that don’t glow very well.

Keep in mind no glow means no show. In other words, you are in danger of taking fire if your patch isn’t glowing.

You don’t want to find out your patch isn’t glowing in the heat of an operation.

IR.Tools™ exclusive reflective materials (SandStorm Technology™) guarantees a glow up to 250% brighter than most IR patches.

You want your stealth movements unmistakable to your team!

4. Your IR Patch Resist White Light Reflection

Are you certain your patch is covert?

Check again. By using a flashlight you can check for any possible white light reflection.

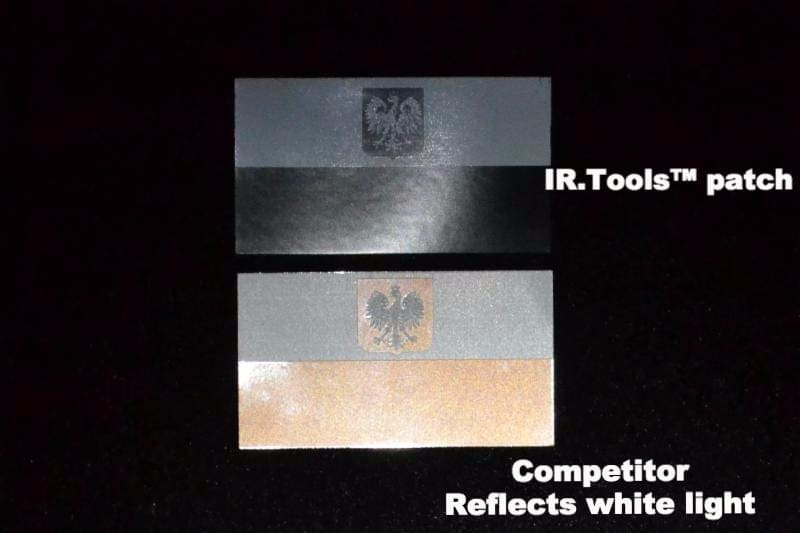

Not all IR patches absorb white light. Failure to absorb the light exposes you to the enemy and friendly fire. See the image to the right. Both patches are advertised as covert IR patches.

The top IR.Tools patch absorbs the white light. This is good. The bottom patch is reflecting white light. Where you see gold it should be black. This is dangerous.

Only a night vision device should be able to pinpoint your location. So you can move about without fear of friendly or enemy fire.

In the end, be sure your covert patch does not reflect white light.

5. Your IR Patch is cool!

Let’s be honest. We all want to wear something that looks cool.

An IR.Tools™ custom design laser patch will deliver on your style.

We have made some intricate designs for military and law enforcement units and have yet to disappoint. And we never sacrifice protection for the design.

In the end, you have a premium IR patch to protect you from a life-altering injury.

IR patches are not the same

It is true, not all IR patches are the same.

Do your homework!

Using a patch that keeps you safe is one assignment you must do.

Your loved ones will be grateful you do.

We help soldiers and officers all over the world stay safer with a premium infrared patch.

Since 2006, Tom has been the driving force behind IR.Tools, dedicated to delivering top-notch infrared solutions to the military, law enforcement, and sportsmen communities.

What began with a single infrared patch has blossomed into a comprehensive store featuring hundreds of IFF patches, vehicle IFF, an extensive suite of thermal training targets, and tools for drone pilots.

Beyond his innovative products, Tom is passionate about educating users on infrared technology and showcasing how advancements in IR can enhance their operations.

Tom holds an MS in Mechanical Engineering from the University of Maryland and an MBA from Regents University.