Introduction

At IR.TOOLS, innovation is not just a goal — it is a responsibility. As part of our ongoing commitment to delivering stronger, more reliable infrared identification products, we are transitioning from traditional woven hook fasteners to advanced molded hook technology.

This upgrade enhances strength, consistency, and manufacturing efficiency — benefits our customers will experience directly in the field.

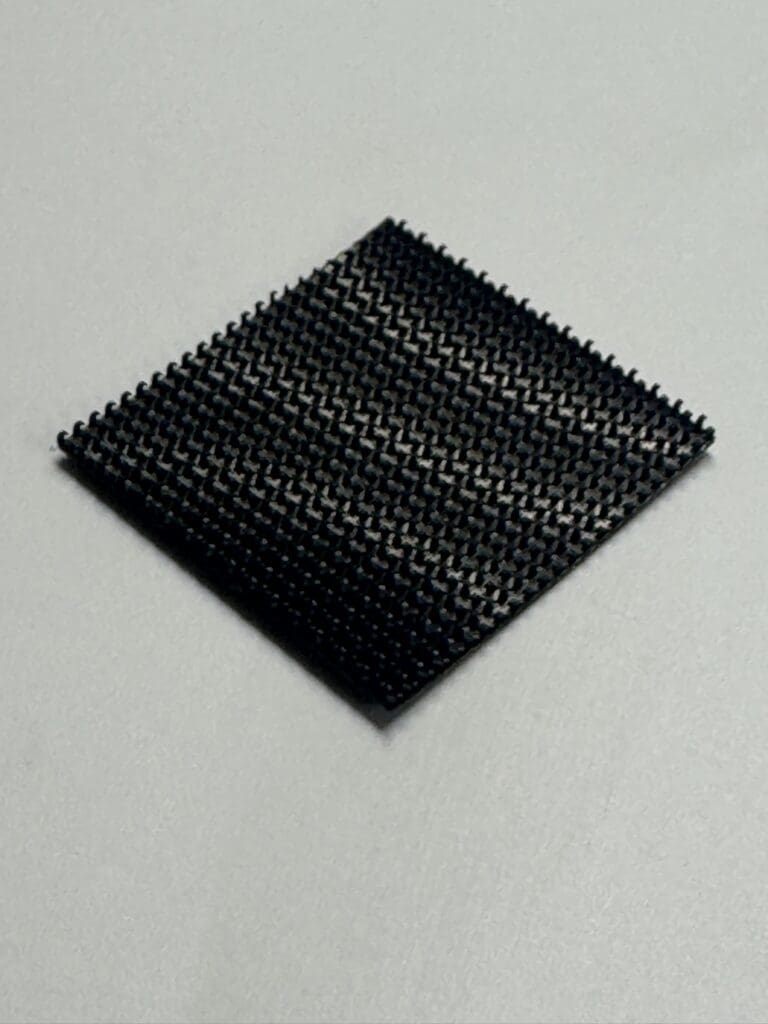

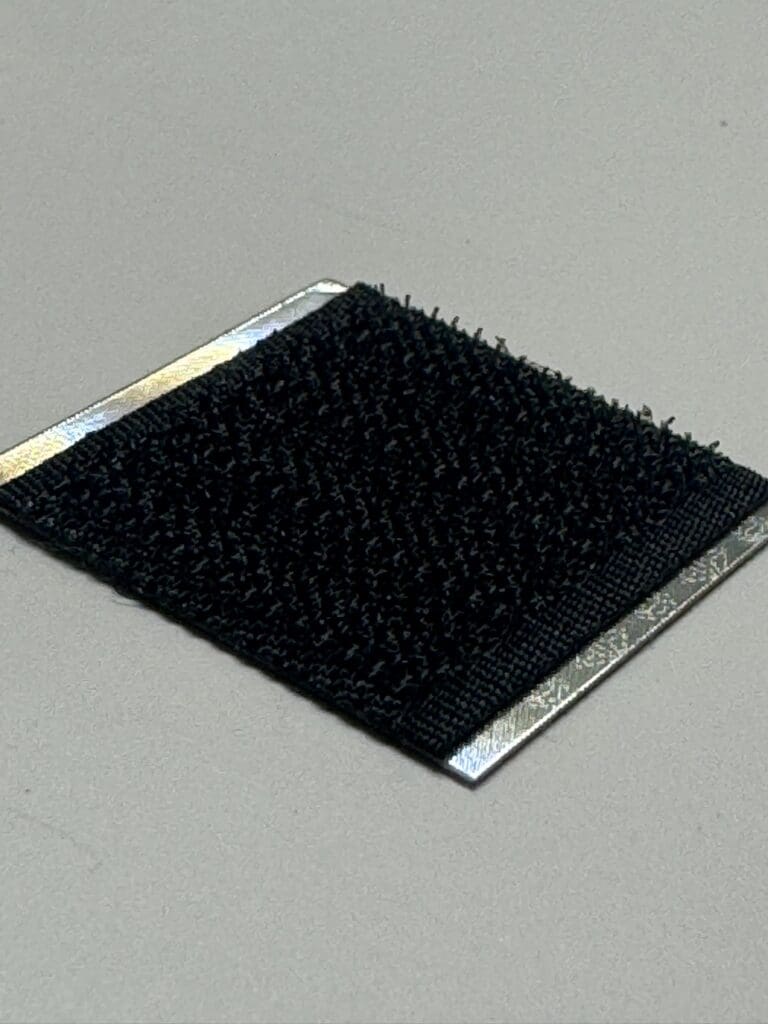

A Clear Upgrade: Woven Hook vs. Molded Hook

After extensive evaluation and supplier trials, molded hook fasteners, though thinner, have demonstrated superior performance across every metric that matters for demanding environments.

Superior Holding Power

Molded hooks are precision‑formed plastic structures with uniform geometry. This design ensures:

- Stronger engagement with loop materials

- More consistent grip over repeated use cycles

- Better resistance to deformation, even under vibration and load

The result? A fastener that stays secure when you need it most.

Manufacturing Efficiency & Quality You Can Trust

Molded hook integrates seamlessly into our production process. Compared to woven hook, it offers:

- Cleaner cuts with less fraying

- Reduced contamination during manufacturing

- Improved compatibility with automated equipment

- Tighter dimensional tolerances for consistent quality

This streamlined performance means faster production, fewer defects, and more reliable results across every order.

What This Means for You

Choosing molded hook brings several customer‑focused advantages:

- Improved reliability — better attachment strength during mission‑critical use

- Longer product life — molded hooks maintain performance over repeated openings

- Cleaner interfaces — reduced debris and fraying keep your gear functioning properly

- Uniform quality — consistent performance across production lots

Compatibility: No Change to Your Existing Gear

Molded hooks work seamlessly with standard woven and knit loop materials already in the field.

If a specific military specification or project requires woven hook, IR.TOOLS will continue supplying woven hook as needed.

Our Commitment to Your Mission

Transitioning to molded hook is more than a manufacturing upgrade — it’s part of IR.TOOLS’ mission to provide the most reliable infrared markers and gear on the market.

By adopting molded hook:

- We strengthen attachment integrity

- We enhance manufacturing precision

- We deliver gear that performs when it matters most

Thank you for trusting IR.TOOLS. We are committed to innovating with purpose — and always with your success in mind.