The military has used thermal shooting targets for years to train with their advanced thermal scopes.

The first targets were all “active.” This means they were heated up with flames, electricity, and chemicals—more than once targets went up in flame.

Then one fateful day a technician was electrocuted (he is fine) tending to an electrical thermal target. This event started a friend of mine thinking.

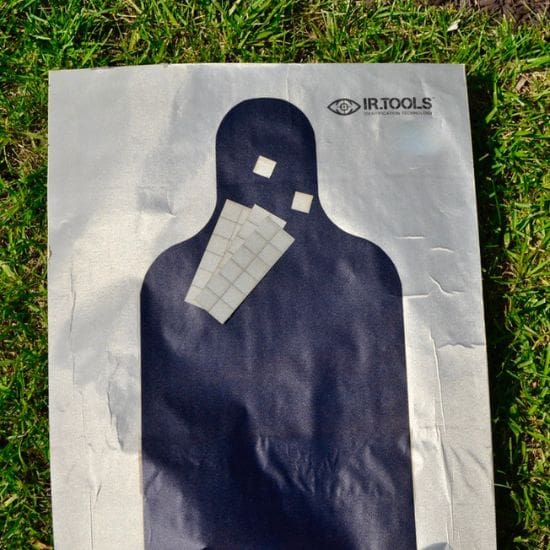

His thinking led him to create a SAFE passive thermal film for shooting targets.

Today the military, law enforcement, and gun enthusiasts use this target to train with their advanced scopes. And there is no danger of the target or you going up in smoke.

But safety is not the only benefit of training with passive thermal targets.

Discover the 6 advantages of passive thermal shooting targets.

1. Easy to Use

2. Custom Images

Customize your training with a high resolution image of your choice. Bad guys, trucks, jeeps, tanks, munitions, etc…

3. Cost Effective

4. Repair, Zeroing, Point of Aim

5. Complex Training Options

The variety of high resolution images makes it easy to create shoot/no shoot and other more complex training scenarios.

6. Ease of Transport

While the advantages to train with passive thermal shooting targets are exciting, we also recommend your training include powered thermal targets.

Access to both forms of targets will give you a versatile, effective training experience.

Read more… One Stop for All Your Thermal Targets.

You are welcome to comment on this blog or contact me with any questions tboyer@ir.tools or call 443.292.8885.

Stay safe!

Since 2006, Tom has been the driving force behind IR.Tools, dedicated to delivering top-notch infrared solutions to the military, law enforcement, and sportsmen communities.

What began with a single infrared patch has blossomed into a comprehensive store featuring hundreds of IFF patches, vehicle IFF, an extensive suite of thermal training targets, and tools for drone pilots.

Beyond his innovative products, Tom is passionate about educating users on infrared technology and showcasing how advancements in IR can enhance their operations.

Tom holds an MS in Mechanical Engineering from the University of Maryland and an MBA from Regents University.